The Chronicles of Dolly the Truss

“Here ye, Here ye, though we come forth in loving remembrance of the loyal and resilient bridge that was Dolly… we have congregated to celebrate a life of much success and fortitude.” –P. Deacon Fred

Plans

______________________________

Performance

Conclusion

Our bridge failed because of a bunch of small mistakes rather than one large one. This means that the solutions to these mistakes are relatively simple and would be easy to fix the next time round. I've made a YouTube video commemorating the death of beloved Dolly, which you can see here:

http://www.youtube.com/watch?v=7w_N_THxkzI

Plans

______________________________

Performance

Dolly’s Performance

Dolly, was not heavy, as a matter of fact, quite the opposite. Her structure weighed 80 grams. You may think now that she was frail, but you are wrong. Her miraculous members supported 3.2 kilograms, making her extremely strong for her size. The ratio from her weight to strength was 39.5.

Dolly’s Inevitable Failure

After being tested to her point of maximum tolerance, Dolly, gave out with a splintering sound that made even the most headstrong cringe. But why did she snap then and there? After some video analysis we determined that a tiny error was part of the issue. If you look at the wood that was used to attach the bucket, you’ll see that there is a hole. That hole was supposed to go on the right side, making up for the fact that the wood had to be off-centre. Here’s a diagram of that.

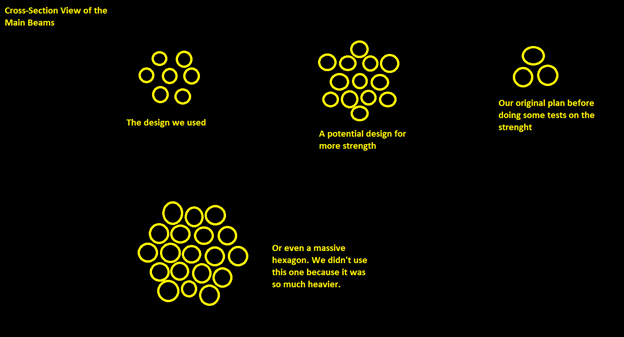

But instead of putting the hole on the correct side, to make up for the extra length, we rushed, and put the wood in incorrectly, making the right side heavier. This may have contributed to the failure of that part of Dolly. Another thing was that the main beams, the two running along the entire length of Dolly, were maybe a bit too thin. I’ve come up with some alternate designs we could have used for them.

The one third from left was our original plan, but we abandoned it because it was extremely weak. The star has some potential though. We haven’t had the opportunity to test that yet though. That gives us a nice segway into our next part: How to Improve Our Design.

How we could have improved our design.

There are many things we could do to improve this design. We think that by adding vertical members, we could have slowed the snapping of our diagonal trusses by reducing the compression on them. Here’s an example of what I mean:

You can see that when the bottom started to flex, the truss attached to that region got compressed really strongly. Maybe if we’d made the bottom a bit more rigid like mentioned earlier, it wouldn’t have snapped so suddenly. Another problem with our design was the lack of a distinct hole in the deck for the bolt to go through. This was a problem that lead to the off centre wood which contributed to the failure. Finally we’d add more webs on the deck to distribute the weight more evenly on the bridge.

If we were to complete this project again…

We would use the same design, although with the modifications specified earlier. It was already quite good, but with the changes it would be much better.

List of Changes We’d Make

- Vertical Members

- Stronger Beams on Bottom

- More surface for the deck to distribute weight more evenly (see figure below)

We looked closely at the structure of Caleb and Alec’s bridge and noticed something we would take from them. We referred to their bridge as ‘Frosty’ because it looked like it had been frosted. The reason it looked that way though was that they’d coated the components of the bridge with a thin layer of glue holding it together. See this diagram for an explanation.

Conclusion

Our bridge failed because of a bunch of small mistakes rather than one large one. This means that the solutions to these mistakes are relatively simple and would be easy to fix the next time round. I've made a YouTube video commemorating the death of beloved Dolly, which you can see here: